Improve Your Manufacturing Process

Choosing a light-curing system that offers flexible curing options, to provide complete cures and speed up assembly times, is critical to the entire manufacturing process.

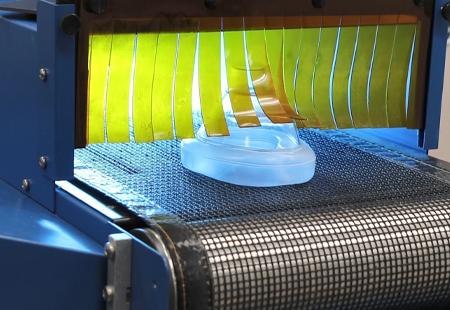

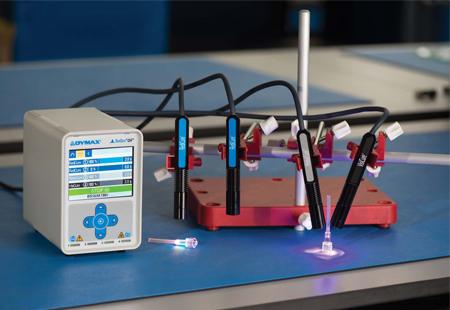

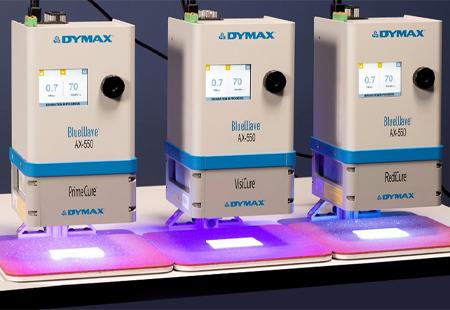

Dymax has a complete line of UV/LED light-curing spot, flood, and conveyor systems that utilize medium-to-high-intensity light energy to effectively cure adhesives, coatings, and inks in seconds.

Along with efficiency, this equipment provides users with additional benefits:

- Traditional broad-spectrum UV bulb or LED arrays to ensure the proper wavelength requirements

- Fast, "on-demand" cure times between 1-30 seconds increase throughput

- Stand-alone equipment or integrate into high-speed automated manufacturing lines for large-volume applications

- Design custom systems with accessories for flexible curing capability

- Try & Buy Program enables users to test drive equipment and ensure it meets their needs before purchase

Need more information? Take a look at our light-curing equipment selector guide for product details and specifications.